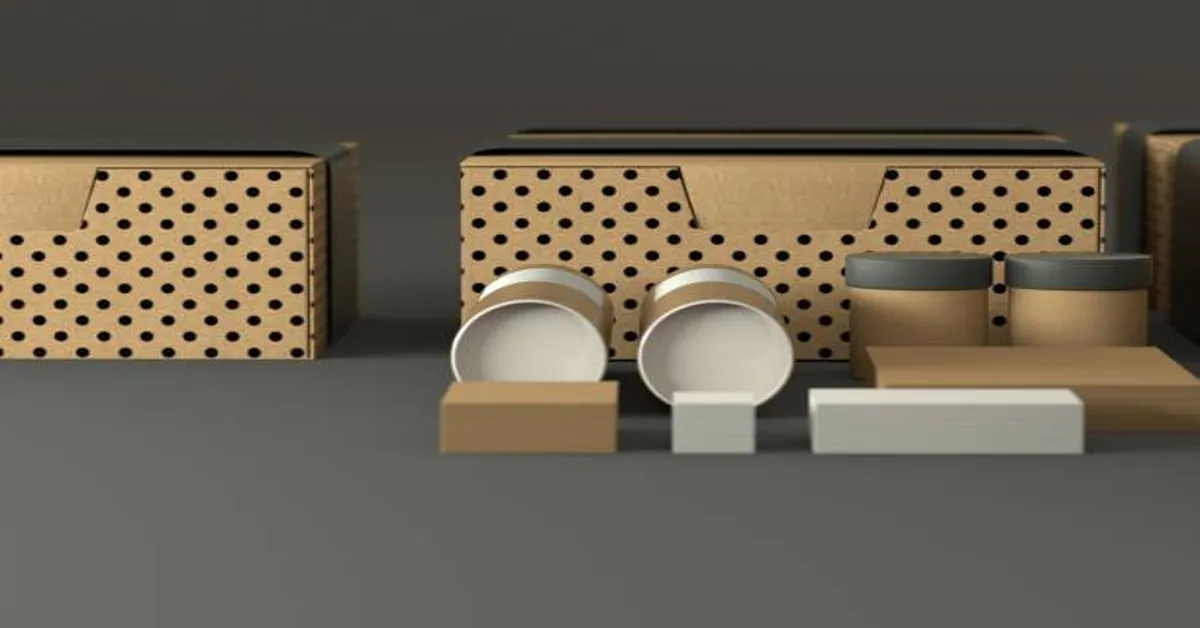

In a world where sustainable packaging and responsible consumption are becoming more important with each passing day, materials like cardboard, paperboard, and compostable fibers are replacing traditional plastics and foams. One often overlooked, yet incredibly functional item in this revolution is the Pappedeckel—a German term that translates to cardboard lid or paperboard cover in English. While it may sound simple, a Pappedeckel represents a surprisingly essential piece of everyday design, impacting industries from food and beverage to pharmaceuticals, cosmetics, and even shipping.

This article provides a detailed look into the Pappedeckel: its material composition, structural design, historical development, environmental significance, and various real-world applications. We will explore how these cardboard lids serve a variety of industries, why they are chosen over alternative materials, and how they contribute to sustainability efforts across the globe.

Let’s take a comprehensive journey through the world of the Pappedeckel, a product that is more significant than it appears on the surface.

Understanding the Term “Pappedeckel”

The German compound word “Pappedeckel” is formed from “Pappe” meaning cardboard or paperboard, and “Deckel” meaning lid or cover. Together, the word literally means cardboard lid. In German-speaking countries, it is a common term used to refer to any form of cardboard or thick paper cover that seals, protects, or tops off a container, box, or cup.

However, the simplicity of the term does not reflect the sophistication involved in its design, manufacturing, and practical application. The Pappedeckel is not just a disposable cover—it is a critical component of a sustainable packaging ecosystem.

Material Composition: What Is a Pappedeckel Made Of?

A standard Pappedeckel is typically made from paperboard or compressed cellulose fiber, often derived from recycled paper products. The base material is layered and compressed to form a stiff, durable sheet that can withstand bending, temperature changes, and minor moisture exposure.

In more specialized applications, a Pappedeckel may be coated or treated with the following:

- Food-grade sealants to resist moisture or grease.

- Biodegradable waxes or PLA (polylactic acid) coatings for compostability.

- Ink-safe printing surfaces for logos, branding, or product information.

- Laminated layers for thermal resistance, especially when used on hot beverage cups.

Importantly, the production process avoids the use of plastic wherever possible, unless required for specific protective purposes. As sustainability becomes a defining issue of our time, manufacturers increasingly turn to biodegradable and recyclable materials to produce Pappedeckel that meet both regulatory and consumer standards.

Historical Use and Evolution of Pappedeckel

Cardboard as a material has been in use since the early 1800s, primarily in the form of rigid boxes for packaging and storage. However, the cardboard lid or Pappedeckel found its mainstream utility during the 20th century, particularly with the rise of mass consumerism and fast food culture.

Early Pappedeckel versions were basic circular or square cutouts placed over containers to keep contents from spilling or being contaminated. They were especially useful in cafeterias, outdoor vendors, and transit packaging.

Over time, as packaging standards evolved, so did the design of the Pappedeckel. Engineers and manufacturers began to add ribbed textures, pressure seals, and interlocking flaps, allowing the lid to stay firmly in place even during movement. With growing concerns about plastic waste in the late 20th and early 21st centuries, the Pappedeckel regained prominence as an eco-friendly alternative to plastic and Styrofoam lids.

Design and Engineering Considerations

Despite its plain appearance, the Pappedeckel is a product of clever engineering. The lid must serve multiple purposes:

- Seal the container effectively to prevent leakage or contamination.

- Be easy to apply and remove, especially in food service environments.

- Withstand temperature variations, such as the heat from a coffee cup or cold from a refrigerated yogurt container.

- Maintain structural integrity even when exposed to moisture or oils.

Some important engineering aspects include:

1. Rim Fit and Grip Design

Pappedeckel are often designed with indented or folded rims that grip the lip of the container. This prevents slipping and ensures the lid stays in place during transport.

2. Scored Folding Lines

For foldable lids, especially in packaging like pizza boxes or large containers, manufacturers add score lines to aid folding, locking, and stacking.

3. Multi-Layer Bonding

Many high-performance Pappedeckel products include two or more layers bonded together to enhance strength while remaining lightweight.

4. Customization

To accommodate branding, Pappedeckel can be printed with high-resolution logos, product information, or QR codes. This helps promote brand identity while serving a practical function.

Applications of Pappedeckel Across Industries

The true value of the Pappedeckel lies in its wide applicability. Though most commonly associated with coffee cups or takeaway food containers, it has far-reaching uses.

1. Food and Beverage

Perhaps the most visible use of Pappedeckel is in the takeaway food and drinks industry. Cardboard lids are used on:

- Coffee and tea cups.

- Yogurt and dessert containers.

- Soup bowls and rice containers.

- Bakery and pastry boxes.

These lids not only prevent spills but also offer an eco-friendly branding opportunity for companies trying to align with green values.

2. Pharmaceuticals

In the pharmaceutical world, cardboard seals or liners are often used to cover pill containers, ointment jars, or over-the-counter medicine packages. These Pappedeckel must meet hygiene and safety standards and are usually designed to be tamper-evident.

3. Retail and Cosmetics

In high-end retail or cosmetic packaging, Pappe deckel are employed in premium unboxing experiences. Lids on perfume boxes, cream jars, or gift containers often use thick, textured paperboard with embossed or gold-foil branding to enhance aesthetics.

4. Shipping and E-commerce

Shipping boxes for e-commerce use Pappe deckel as internal protective layers, lid inserts, or product dividers. These provide shock resistance while remaining lightweight.

5. Agricultural Packaging

In farm-to-table delivery services or organic produce boxes, cardboard lids protect items like eggs, berries, and herbs without introducing plastic into the ecosystem.

Environmental Impact and Sustainability

Pappe deckel products are frequently promoted for their low environmental footprint, especially when compared to plastic or polystyrene lids. Their eco-sustainability stems from several key features:

1. Recyclability

Cardboard lids made from virgin or recycled paperboard are often 100% recyclable, provided they are not contaminated by food waste or non-recyclable coatings.

2. Biodegradability

Many Pappe deckel products decompose naturally within weeks or months in composting environments, unlike plastics which can persist for centuries.

3. Low Carbon Manufacturing

Compared to synthetic polymers, producing cardboard involves less energy and fewer toxic emissions, particularly when renewable energy is used in manufacturing.

4. Reusable Innovations

Some Pappe deckel lids are now designed for short-term reuse, especially in local food systems and refill programs.

However, the industry is still evolving. Not all Pappe deckel are created equally; lids with synthetic coatings or mixed materials can complicate recycling processes. Manufacturers are actively working on innovations like plant-based waterproofing, minimalist adhesives, and fully compostable inks to enhance sustainability.

Consumer Behavior and Adoption

Consumer demand plays a significant role in the success and spread of Pappe deckel products. As more individuals become environmentally conscious, the preference for biodegradable packaging is growing. Brands that adopt Pappe deckel solutions often see:

- Improved customer loyalty, especially among eco-aware demographics.

- Brand differentiation in competitive markets.

- Positive social media engagement from aesthetically pleasing and earth-friendly packaging.

Additionally, many countries are passing legislation that bans single-use plastics, making cardboard-based packaging not just an ethical choice, but a legal necessity.

Challenges in Pappedeckel Usage

Despite its many advantages, the use of Pappe deckel is not without limitations.

1. Moisture Sensitivity

Without proper coatings or treatments, cardboard lids may become soggy when in contact with liquids or steam.

2. Structural Weakness in Extreme Conditions

While excellent for most everyday applications, cardboard lids may deform under high humidity or weight, making them unsuitable for all packaging scenarios.

3. Recycling Confusion

If a Pappe deckel is coated with non-compostable or plastic-based linings, consumers may be unsure about whether it belongs in compost, recycling, or general waste.

To counter these issues, companies and consumers alike must prioritize education and innovation. Labels on Pappe deckel can indicate disposal methods, and manufacturers can improve material integrity through bio-based technological advances.

The Future of Pappedeckel

Looking ahead, the future of the Pappe deckel is promising. As circular economy principles become the gold standard for product design, cardboard lids will continue to evolve in form, function, and efficiency.

Some innovations on the horizon include:

- Edible lids for short-term food products.

- Smart Pappedeckel with embedded RFID for inventory tracking.

- Color-changing heat-sensitive lids for beverages.

- Hybrid paper-fiber composites that increase strength while remaining compostable.

The combination of environmental urgency and technological advancement positions the humble Pappe deckel to become a keystone in sustainable product design and consumer packaging.

Conclusion

From a simple cardboard lid to a highly engineered and sustainable packaging solution, the Pappedeckel has undergone significant transformation. It is now a symbol of responsible design, blending functionality with environmental consciousness. As businesses seek to reduce their ecological footprints and consumers demand greener alternatives, products like the Pappe deckel will continue to play an essential role in the future of global packaging.

Its utility across industries—from food to pharmaceuticals, shipping to cosmetics—proves that even the most unassuming objects can carry enormous significance when paired with thoughtful design and responsible production.

ALSO READ: Blazertje: A Versatile Statement in Contemporary Wardrobe Culture

FAQs About Pappedeckel

1. What is a Pappedeckel used for?

A Pappedeckel is used as a cardboard lid for containers, commonly found in food packaging, retail boxes, shipping, and cosmetics.

2. Are Pappedeckel products environmentally friendly?

Yes, most Pappedeckel lids are recyclable and biodegradable, especially when made from untreated or compostable materials.

3. Can Pappedeckel be used with hot drinks like coffee?

Yes, specially treated Pappedeckel lids are designed to resist heat and moisture, making them ideal for hot beverages.

4. Is Pappedeckel packaging suitable for industrial use?

Absolutely. Many businesses use Pappedeckel in bulk packaging, e-commerce, pharmaceuticals, and storage to reduce plastic usage.

5. Are there different types of Pappedeckel materials?

Yes, Pappedeckel can be made from virgin paperboard, recycled cardboard, coated fiberboard, or biodegradable composites depending on the application.