Tooling is one of the most crucial aspects of manufacturing and product development. At its core, the term “tooling It” refers to the process of designing, engineering, and producing the physical tools, fixtures, molds, dies, gauges, jigs, and other specialized equipment required to manufacture products efficiently and accurately. In many industries—automotive, aerospace, electronics, consumer goods—It is the bridge between a conceptual design and a tangible product.

While raw materials and labor power the manufacturing process, it is “tooling It” that ensures consistency, precision, and scalability. Without the right tooling, even the most advanced production systems cannot function optimally. Tooling shapes the way materials are cut, molded, assembled, and finished. It dictates product quality, production cost, speed, and overall competitiveness.

In the past, tooling was predominantly a manual and mechanical process. Craftsmen relied on lathes, milling machines, and hand tools to create production aids. Today, It has evolved into a sophisticated field incorporating CNC (Computer Numerical Control) machining, additive manufacturing, CAD/CAM design software, and high-performance materials. Modern tooling is not just about producing physical aids—it’s about engineering efficiency into every stage of manufacturing.

This article dives deeply into the world of “tooling It”, exploring its types, processes, applications, materials, design considerations, and emerging trends. Whether you’re a student of mechanical engineering, a manufacturing professional, or simply curious about how everyday products are made, understanding tooling will give you valuable insights into the backbone of industrial production.

The Role of Tooling in Manufacturing

Tooling plays multiple interconnected roles in production:

- Product Accuracy and Precision – Tooling ensures that every component matches design specifications within tight tolerances, which is essential for parts that must fit together precisely.

- Repeatability – With proper tooling, thousands or even millions of identical components can be produced consistently.

- Efficiency – Well-designed “tooling It” reduces cycle time, minimizes waste, and optimizes machine usage.

- Cost Control – While tooling can be expensive to produce, its long-term benefits include lower production costs per unit.

- Safety – Proper jigs, fixtures, and guards improve operator safety by reducing the need for manual handling.

- Scalability – From prototype to mass production, “tooling It” enables scaling without compromising quality.

Think of “tooling It” as the “invisible infrastructure” of manufacturing—often unseen by the consumer, but absolutely vital for delivering high-quality products at competitive prices.

Types of Tooling

Tooling can be classified in several ways: by function, by manufacturing stage, or by the type of manufacturing process it supports. Below is a comprehensive breakdown.

1. Production Tooling

Production “tooling It” refers to tools, dies, molds, and fixtures that are used during mass manufacturing. They are designed for durability and high-volume use.

- Injection Molds – Used in plastics manufacturing to shape molten plastic into precise forms.

- Stamping Dies – Used for cutting and shaping sheet metal into parts.

- Extrusion Dies – For producing continuous profiles like pipes or window frames.

- Casting Molds – Used in metal casting processes to form parts.

2. Prototype Tooling

Prototype tooling is used in product development stages to create initial versions of a part for testing before mass production. This type prioritizes speed and flexibility over durability.

- Soft Tooling – Made from aluminum or resin; used for small runs and design verification.

- 3D Printed Tooling – Additively manufactured for quick turnaround.

3. Jigs and Fixtures

Jigs and fixtures hold workpieces securely and guide manufacturing tools.

| Type | Purpose | Example |

|---|---|---|

| Jigs | Guide cutting tools | Drill jig |

| Fixtures | Hold workpieces in place | Welding fixture |

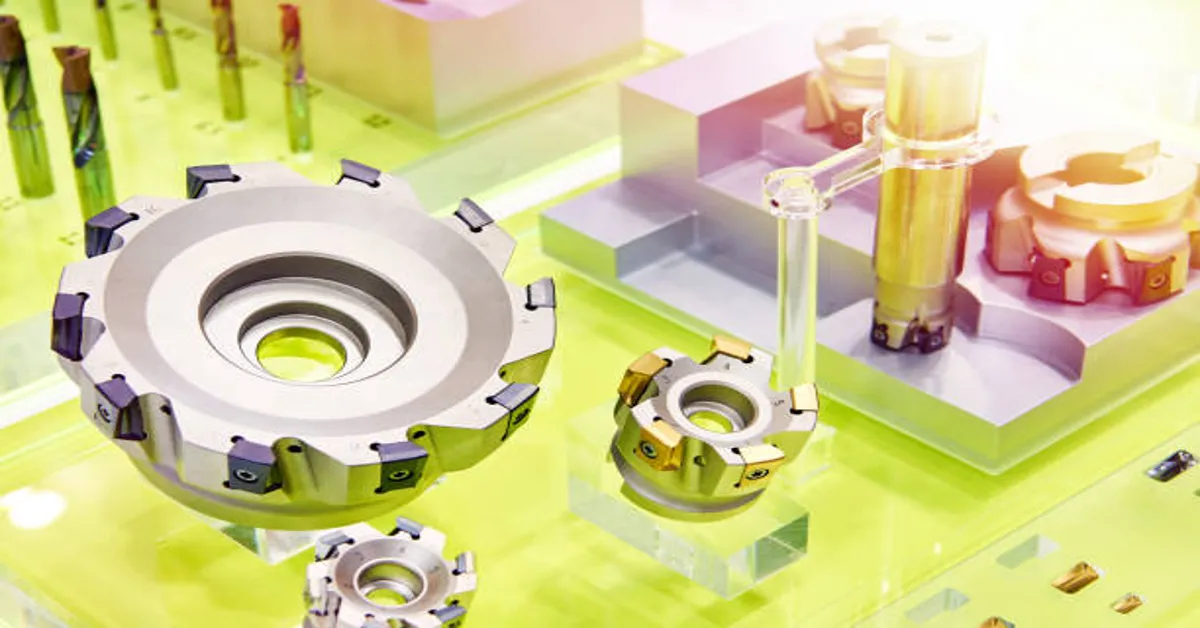

4. Cutting Tools

Cutting tools physically remove material to form parts.

- Milling Cutters

- Drills

- Lathe Tools

- Broaches

5. Inspection Tooling

Inspection tooling ensures quality by checking dimensions and tolerances.

- Gauges

- Templates

- Coordinate Measuring Machine (CMM) Fixtures

Tooling Materials

The material used for tooling must be carefully selected based on durability, heat resistance, wear resistance, and cost.

| Tooling Material | Advantages | Applications |

|---|---|---|

| Tool Steel | High hardness, wear resistance | Cutting tools, dies |

| Carbide | Excellent hardness, heat resistance | High-speed cutting |

| Aluminum | Lightweight, easy to machine | Prototype molds |

| Resin | Low cost, quick turnaround | Prototype tooling |

| Hardened Steel | Long life in production | High-volume molds |

Tooling Design Process

Designing tooling involves multiple stages:

- Requirement Analysis – Understanding product geometry, production volume, and tolerance requirements.

- Material Selection – Choosing the right material for the expected tool life and process.

- CAD Modeling – Creating 3D designs using software like SolidWorks or AutoCAD.

- Simulation and Testing – Running digital simulations for stress, thermal load, and wear patterns.

- Manufacturing – Using CNC machining, EDM, or additive manufacturing to produce the tooling.

- Trial Runs – Testing the tooling in real production conditions.

- Refinement – Making adjustments to improve performance and durability.

Tooling in Different Industries

Tooling requirements vary across sectors. Let’s look at a few examples:

| Industry | Primary Tooling Needs | Special Considerations |

|---|---|---|

| Automotive | Stamping dies, welding fixtures, injection molds | High durability, tight tolerances |

| Aerospace | Precision machining tools, composite molds | Lightweight materials, strict safety standards |

| Electronics | Micro-molds, PCB assembly jigs | Miniaturization, high repeatability |

| Consumer Goods | Plastic molds, packaging dies | High aesthetics, fast cycle time |

| Medical Devices | Cleanroom-compatible tooling | Biocompatibility, regulatory compliance |

Tooling Maintenance and Lifecycle

Tooling represents a significant investment, so maintenance is essential to extend its life.

- Preventive Maintenance – Regular cleaning, lubrication, and inspection.

- Predictive Maintenance – Using sensors and data analytics to predict wear before failure.

- Refurbishment – Re-grinding, re-coating, or replacing worn components.

- Tool Tracking – Maintaining records of usage cycles, repairs, and performance.

Typical tooling lifespan varies depending on material, usage, and maintenance. For example, a hardened steel injection mold may last over a million cycles, whereas an aluminum prototype mold may only last a few thousand.

Cost Factors in Tooling

Tooling costs depend on:

- Complexity of design

- Material used

- Production volume requirements

- Precision tolerances

- Manufacturing technology used (CNC, EDM, additive manufacturing)

Example Table: Tooling Cost Range

| Tool Type | Low Complexity Cost | High Complexity Cost |

|---|---|---|

| Injection Mold | $5,000 | $150,000+ |

| Stamping Die | $3,000 | $100,000+ |

| CNC Fixture | $500 | $10,000+ |

Emerging Trends in Tooling

- Additive Manufacturing for Tooling – 3D printing is now used to make molds, dies, and fixtures faster.

- Hybrid Tooling – Combining conventional machining and additive manufacturing.

- Advanced Coatings – PVD and CVD coatings increase tool life.

- Digital Twins – Virtual models of tooling for predictive analysis.

- Modular Tooling Systems – Interchangeable components for flexibility.

Conclusion

Tooling is the foundation of modern manufacturing, ensuring that products are made with precision, consistency, and efficiency. From initial prototypes to mass production, the right tooling strategy can dramatically influence product quality, production speed, and overall profitability. As technology evolves, tooling continues to advance with smarter designs, new materials, and data-driven maintenance approaches. For manufacturers, investing in well-engineered tooling is not just a cost—it’s a strategic advantage.

ALSO READ: Disease and “Dis-Ease”: A Comprehensive Understanding

Frequently Asked Questions (FAQs)

1. What is tooling in manufacturing?

Tooling refers to the design and production of specialized tools, molds, fixtures, and dies needed for manufacturing parts efficiently.

2. Why is tooling important?

It ensures product accuracy, repeatability, efficiency, and safety while reducing production costs over time.

3. What are the main types of tooling?

They include production tooling, prototype tooling, jigs and fixtures, cutting tools, and inspection tooling.

4. How long does tooling last?

It depends on the material, usage, and maintenance, ranging from a few thousand to over a million cycles.

5. What are recent innovations in tooling?

3D-printed tooling, digital twins, advanced coatings, and modular systems are transforming the industry.